CUSTOMER ADVANTAGES:

- Basic concept made of anodized aluminum profile

- Reflector sheet made of high reflective steel

- Adaptable to all common aluminum profile construction kits

- Customized to your individual heating installation

- Variable installation due to the T-slots

- Prepared for the installation of temperature monitoring systems or individual coverings

- Integrated or customized air supply

- Designed to supply the required power for your process by short or medium wave in round or double tube design

- Combined with a comprehensive switch board cabinet, Type IC…, if required with an automatic emitter output and product temperature control, or connected to customer control cabinet

TECHNICAL DATA:

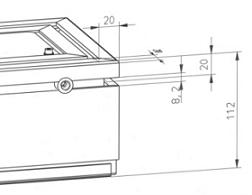

- Hight housing: approx. 112 mm

- Hight incl. axial-fan: approx. 152 mm

- Width variable: up to 2.000 mm

- Length variable: up to 4.000 mm

COOL AIR SUPPLY VIA:

- Temperature of the module is monitored by an integrated thermo switch

- VBG 23: please pay attention to regulations concerning explosion.

ELECTRICAL CONNECTION VIA:

- heavy plug-type connectors

- Internal terminals and screwed cable gland

- Designed for the connection cables Oil flex or heat resistant cable >100 °C

ADDITIONAL:

- Weight: approx. 40 kg/m²

IR MODULE 36 KW SYSTEM FOR PLASTIC CURING:

- size 1.350 x 400 x 112 mm

- structure frame made by profile L

- electr. power: 36 kW / 400 V

- 9 pc. fast medium wave single tube star 4.0 kWW

- axial fan for cooling

- heavy duty connector

- optical pyrometer

- exhaust device

IR MODUL 3.0 KW – SYSTEM FOR HEATING CD BONDING:

- Size: 440 x 290 x 112 mm

- Housing: anodized aluminum profile L

- Electrical power: 3.0 kW / 230 V

- 2 x 3 radiators short-wave 0.5 kW

- optical pyrometer

- Axial fan for cooling

- Harting connectors

IR MODULE 3.2 KW SYSTEM FOR PLASTIC HEATING:

- size 150 x 280 x 82 mm

- housing aluminum sheet metal

- electr. power: 3.2 kW / 230 V

- 2 pc. short wave 1.6 kW

- axial fan for cooling

- heavy duty connector